Realizing ultra-precision machining.

Honing Machines

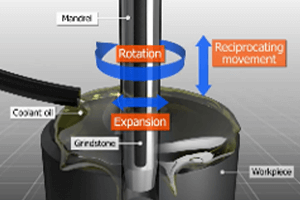

The Honing Process

Honing is a precision machining process in which surface contact grinding is performed in a large volume of grinding liquid by applying pressure to the inner surface of a hole while rotating and reciprocating a hone, also known as a honing stone. A distinctive cross hatching is formed on the finished surface, creating an excellent sliding surface. Nissin employs an automatic machine expansion method using a screw-wedge system in the stone expansion system, which is the heart of the honing machine. Accurate micro infeed (constant speed expansion) is synchronized with the stroke, improving the surface roughness accuracy while enabling correction of the shape accuracy‒an area of high-precision machining even in the mass-production process‒and ultra-precision machining with a small finishing tolerance.

Machining Examples

F25G-M3SR

-

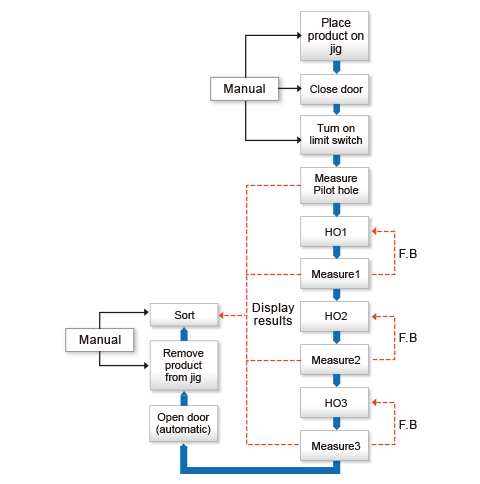

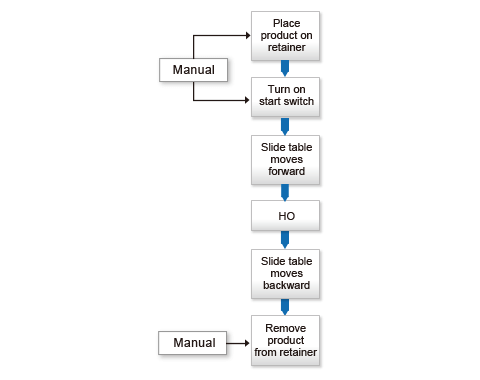

Machining cycle

-

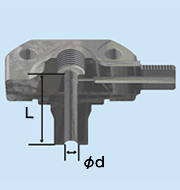

Workpiece

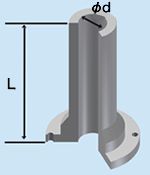

| Machined product | Cylinder | Required machining accuracy | Machining accuracy | |

|---|---|---|---|---|

| Material | SUS440C | Cylindricity | 2 μm | 1 μm |

| Hardness | HRC 57 to 63 | Roundness | 1 μm | 0.5 μm |

| Machining dimensions | Diameter 7.505 × L 38 | Surface roughness | Ra 0.4 μm | Ra 0.3 μm |

| Stock removal | 25 μm to 45 μm | Machining time | 30 seconds | 30 seconds |

G25-AR2

-

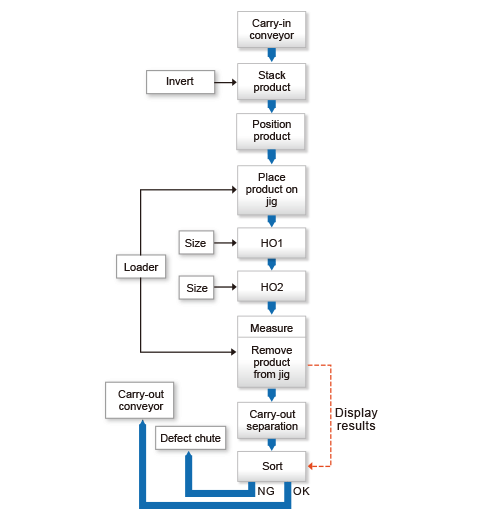

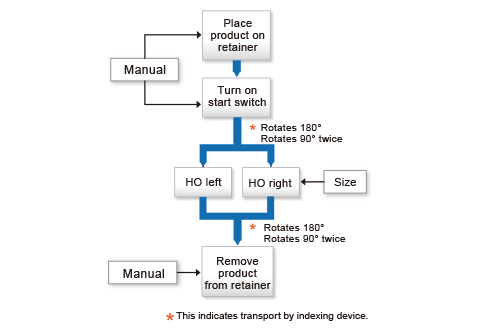

Machining cycle

-

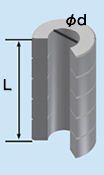

Workpiece

| Machined product | Pinion | Required machining accuracy | Machining accuracy | |

|---|---|---|---|---|

| Material | AG20 | Cylindricity | 5 μm | 2 μm |

| Hardness | Hv 720 to 850 | Roundness | 5 μm | 1 μm |

| Machining dimensions | Diameter 19.65 × L 18.9 |

Surface roughness | Ra 0.8 μm | Ra 0.6 μm |

| Stock removal | 50 μm to 70 μm | Machining time | 40 seconds, 5 workpieces | 40 seconds, 5 workpieces |

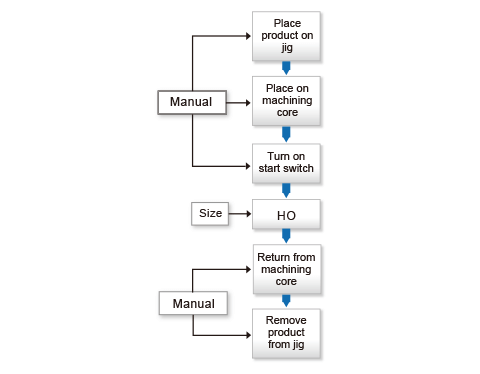

G50-MM1

-

Machining cycle

-

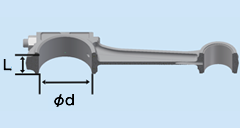

Workpiece

| Machined product | Connecting rod (large end) | Required machining accuracy | Machining accuracy | |

|---|---|---|---|---|

| Material | SCM420 | Straightness | 4 μm | 1.2 μm |

| Hardness | Hv 320 to 380 | Roundness | 5 μm | 1.5 μm |

| Machining dimensions | Diameter 57 × L 30 | Surface roughness | Ra 0.5 μm | Ra 0.2 μm |

| Stock removal | Max. 27 μm | Machining time | 30 seconds | 25 seconds |

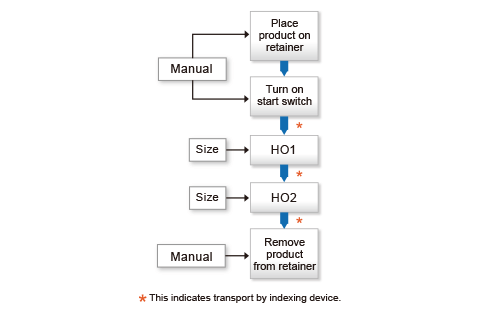

G50-MR2

-

Machining cycle

-

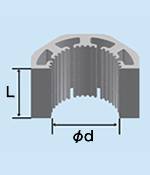

Workpiece

| Machined product | Stator core | Required machining accuracy | Machining accuracy | |

|---|---|---|---|---|

| Material | Silicon steel plate | Cylindricity | — | 3.7 μm |

| Hardness | — | Roundness | 10 μm | 2.9 μm |

| Machining dimensions | Diameter 35 × L 24.5 | Surface roughness | — | — |

| Stock removal | Approx. 65 μm | Machining time | 30 seconds, 3 workpieces | 26 seconds, 3 workpieces |

Note: 3-piece stacked honing

G50L-MM1

-

Machining cycle

-

Workpiece

| Machined product | Barrel | Required machining accuracy | Machining accuracy | |

|---|---|---|---|---|

| Material | SCM415 | Straightness | 2 μm/100 mm | 1.3 μm |

| Hardness | HRC 58 to 64 | Roundness | 2 μm | 0.2 μm |

| Machining dimensions | Diameter 47 × L 300 | Surface roughness | Ra 0.1 μm | Ra 0.07 μm |

| Stock removal | 25 μm | Machining time | — | 403 seconds |

G50-MR2

-

Machining cycle

-

Workpiece

| Machined product | Gear | Required machining accuracy | Machining accuracy | |

|---|---|---|---|---|

| Material | SCr420H | Cylindricity | 6.3 μm | 1.5 μm |

| Hardness | HRA 78 to 83 | Roundness | 6.3 μm | 0.6 μm |

| Machining dimensions | Diameter 50 × L 24 | Surface roughness | Rzmax 3.2 μm | Rzmax 2.0 μm |

| Stock removal | 130 μm | Machining time | 40 seconds | 50 seconds |

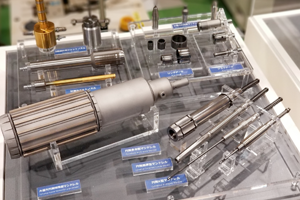

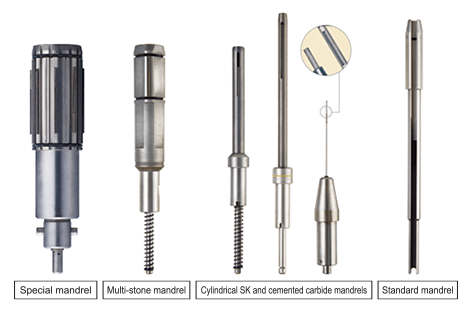

Honing Tools

Nissin original tools support various types of ultra-precision machining

Mandrels

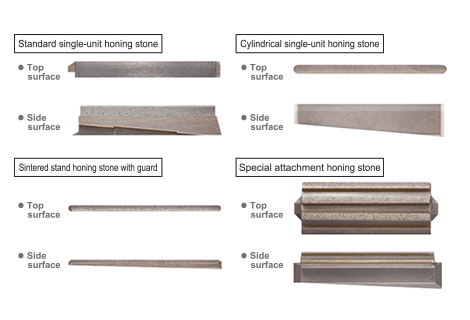

Honing stones

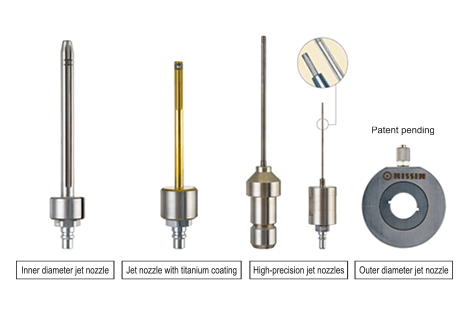

Jet nozzles

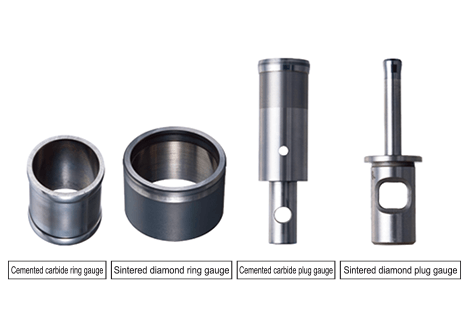

Gauges

Contract Honing

Specialist on the Submicron

Nissin offers development and prototype production, contract production of small-lot products,

and production outsourcing before equipment delivery.

As a submicron specialist, Nissin provides honing machines you can trust.

-

- Hole diameter: 3 mm to 100 mm

- Machining length: Max. 130 mm

(For honing outside this range, contact us for details.)

Major machining workpieces

Automotive parts, motorcycle parts, hydraulic parts, appliance parts, etc.

Solution Examples

Nissin offers a variety of solutions to your needs

- Problem Product to be machined has a small diameter or is thin-walled, long, or irregularly shaped, and required accuracy cannot be achieved with internal grinding or turning.

-

- A thin-walled bushing can be machined, but roundness cannot be achieved due to clamp strain.

- L/Ð is equal to or greater than 10, and the tool overhang is too long, preventing machining.

- Solution We can provide the optimal proposal for a honing machine, jig tool, and machining conditions, even for hard-to-cut parts.

-

Problem You received a machining inquiry, but you are unable to accept the order because the delivery date of the equipment manufacturer is too long.

- You cannot meet the customer’s startup schedule for prototyping and mass-production prototyping.

- Solution We can produce units of equipment and deliver them

with a short turnaround.

In addition, we also provide contract honing.

- Problem You are having tool-related issues.

- You want to reduce cutting tool costs.

- You want to improve yield after tool replacement.

- You want to improve machining accuracy.

- Solution We offer end-to-end solutions from tool selection and quotation for tool evaluation to proposal, production, and delivery.

In addition, our numerous plants and our offices in Tokyo, Nagoya, and Osaka are ready to help you with after-sales service to ensure peace of mind.

- Problem You want to accept an order for a large project, but there are numerous machining issues, and you cannot determine whether additional equipment is needed.

- Solution We offer regular after-sales maintenance and dispatch service technicians around the world to help with everything from quotation for process evaluation to quick troubleshooting.

We encourage you to call or visit your nearest Nissin plant or office for support.

- Problem You are in need of small-lot production but do not want to invest in equipment and do not know where to outsource ultra-precision machining.

- Because the quantity is less than 50 pieces a month, you cannot install your own honing equipment.

- The customer demands improvements because they are not satisfied with the accuracy of machining by hand, alternative machine, or outsourcing.

- Solution We also provide contract honing using Nissin honing machines.

Lineup of Machine Tools

Contact us about our products

| Tel: | +81 772-62-8088 |

|---|---|

| Fax: | +81 772-62-6688 |

| Department in charge of machine tools: | Sales Management Section |