Optimal for multi-product production at a reasonable cost

HOME> Product Information > Machine Tools

To ensure a high level of quality at Nissin, we develop various machine tools in house for precision parts machining. Among these tools, our honing machines are one of the top brands in the industry and are indispensable for ultra-precision honing. We are highly recognized in various industries, including the automotive, motorcycle, general-use engine, hydraulic and pneumatic, appliance, mold, and sewing machine sectors.

As a comprehensive manufacturer of honing machines, Nissin offers total solutions by selecting the optimam element, including the honing machine, honing tools, and jigs.

Here is a look at our original honing tools that support various types of ultra-precision machining.

• Development and prototype production • Contract production of small-lot products • Outsourced production before equipment delivery

Optimal for multi-product production at a reasonable cost

Flexibly supports changes in production without taking up space

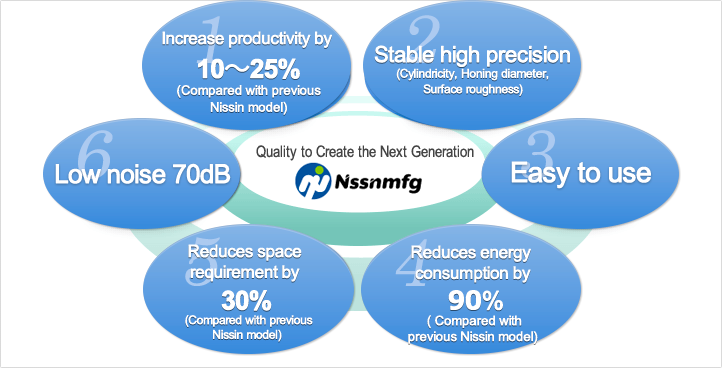

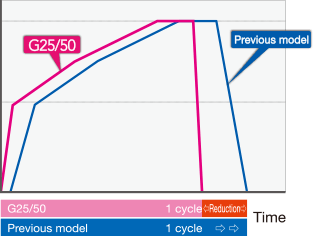

High-speed machining reduces the machining time.

Synchronous tuning stone expansion function ensures high-precision machining.

Stone expansion according to the stroke enables stable machining accuracy and surface roughness

Use the operation screen to check the sequence program and instruction manual.

Automatic adjustment of honing stone overhang position

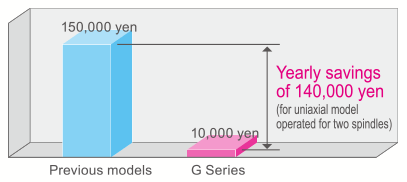

Electricity cost savings of 90% (Compared to existing model)

Save ¥140,000 per year.

Electricity cost (example when compared to existing model)

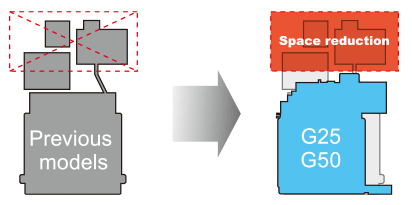

Hydraulic-free design reduces the footprint by 30% compared to the existing model.

Servo motor drive reduces the operation noise.

Pinion gears

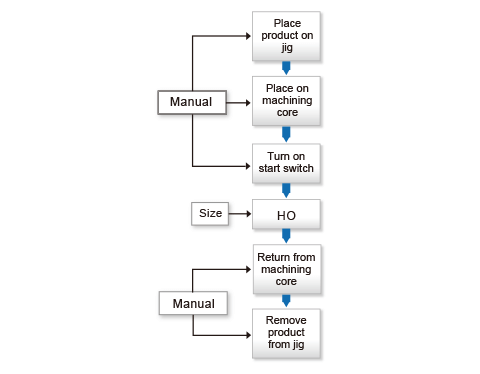

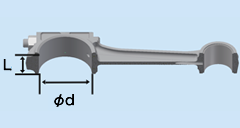

Automotive connecting rods

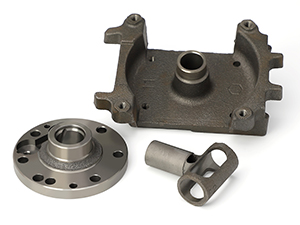

Turbo housings

Rocker arms

Power steering pinion shafts and sleeves

Barrels, nozzles, and cylinders

Compact connecting rods

Various gears

Compressors

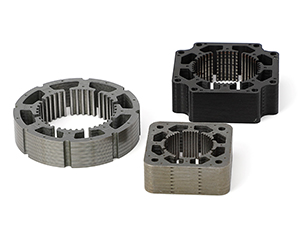

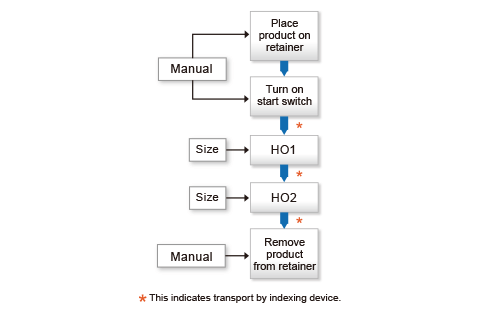

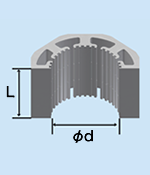

Stator cores

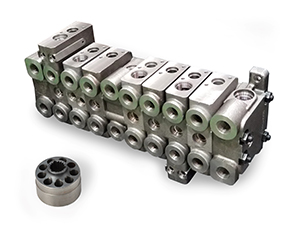

Hydraulic parts

Pneumatic parts

Cylinder block for motor cycle

Conrod for truck

Here are some examples of Nissin high-precision machining.

| Machined product | Cylinder | Required machining accuracy | Machining accuracy | |

|---|---|---|---|---|

| Material | SUS440C | Cylindricity | 2 μm | 1 μm |

| Hardness | HRC 57 to 63 | Roundness | 1 μm | 0.5 μm |

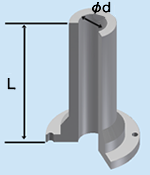

| Machining dimensions | Diameter 7.505 × L 38 | Surface roughness | Ra 0.4 μm | Ra 0.3 μm |

| Stock removal | 25 μm to 45 μm | Machining time | 30 seconds | 30 seconds |

| Machined product | Pinion | Required machining accuracy | Machining accuracy | |

|---|---|---|---|---|

| Material | AG20 | Cylindricity | 5 μm | 2 μm |

| Hardness | Hv 720 to 850 | Roundness | 5 μm | 1 μm |

| Machining dimensions | Diameter 19.65 × L 18.9 | Surface roughness | Ra 0.8 μm | Ra 0.6 μm |

| Stock removal | 50 μm to 70 μm | Machining time | 40 seconds, 5 workpieces | 40 seconds, 5 workpieces |

| Machined product | Connecting rod (large end) | Required machining accuracy | Machining accuracy | |

|---|---|---|---|---|

| Material | SCM420 | Straightness | 4 μm | 1.2 μm |

| Hardness | Hv 320 to 380 | Roundness | 5 μm | 1.5 μm |

| Machining dimensions | Diameter 57 × L 30 | Surface roughness | Ra 0.5 μm | Ra 0.2 μm |

| Stock removal | Max. 27 μm | Machining time | 30 seconds | 25 seconds |

| Machined product | Stator core | Required machining accuracy | Machining accuracy | |

|---|---|---|---|---|

| Material | Silicon steel plate | Cylindricity | — | 3.7 μm |

| Hardness | — | Roundness | 10 μm | 2.9 μm |

| Machining dimensions | Diameter 35 × L 24.5 | Surface roughness | — | — |

| Stock removal | Approx. 65 μm | Machining time | 30 seconds, 3 workpieces | 26 seconds, 3 workpieces |

Note: 3-piece stacked honing

| Machined product | Barrel | Required machining accuracy | Machining accuracy | |

|---|---|---|---|---|

| Material | SCM415 | Straightness | 2 μm/100 mm | 1.3 μm |

| Hardness | HRC 58 to 64 | Roundness | 2 μm | 0.2 μm |

| Machining dimensions | Diameter 47 × L 300 | Surface roughness | Ra 0.1 μm | Ra 0.07 μm |

| Stock removal | 25 μm | Machining time | — | 403 seconds |

| Machined product | Gear | Required machining accuracy | Machining accuracy | |

|---|---|---|---|---|

| Material | SCr420H | Cylindricity | 6.3 μm | 1.5 μm |

| Hardness | HRA 78 to 83 | Roundness | 6.3 μm | 0.6 μm |

| Machining dimensions | Diameter 50 × L 24 | Surface roughness | Rzmax 3.2 μm | Rzmax 2.0 μm |

| Stock removal | 130 μm | Machining time | 40 seconds | 50 seconds |

Contact us about our products

| Tel: | +81 772-62-8088 |

|---|---|

| Fax: | +81 772-62-6688 |

| Department in charge of machine tools: | Sales Management Section |