We provide integrated processing from hot and cold forging and aluminum high pressure die casting to machining, heat treatment, and assembly.

Formed and Fabricated Materials Machining

Forging Technology

Precision forging using a crank press and hammer

We use a die forging method, which uses dies to produce materials for products that require product precision and strength.

Our hot forging mainly forms automotive parts up to the size of your palm.

Our cold forging is used to form fine precision parts that attach to the tip of industrial sewing machines.

Size of hot forging equipment: 1,000 to 1,600 tons

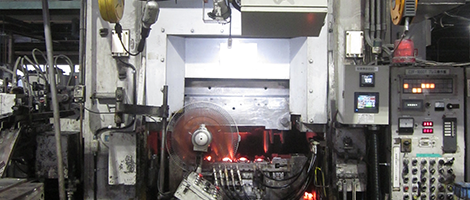

Aluminum High Pressure Die Casting

High-strength die casting uses decompression and local pressurization to minimize internal defects.

Our die casting process is a production method that combines decompression, which is mainly used to improve molten metal flow and reduce entrapped cavities, with local pressurization, which reduces the occurrence of shrinking cavities. We are developing an aluminum business with our main products being functional parts for automotive engines, which are used in extremely harsh environments.

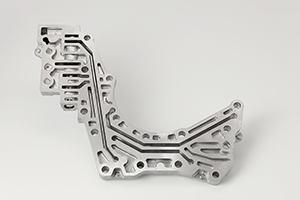

Machining and Finishing

Machining and Finishing Technology

We specialize in machining small, irregularly shaped parts. By using our expertise cultivated over a half century of experience since our founding and proactive improvement activities making the most of our existing facilities, we are improving the efficiency of our general-purpose lines to build dedicated lines for high volume products. We use equipment developed and manufactured in-house for the key finishing process prior to completing a product, and we are working to increase our precision.

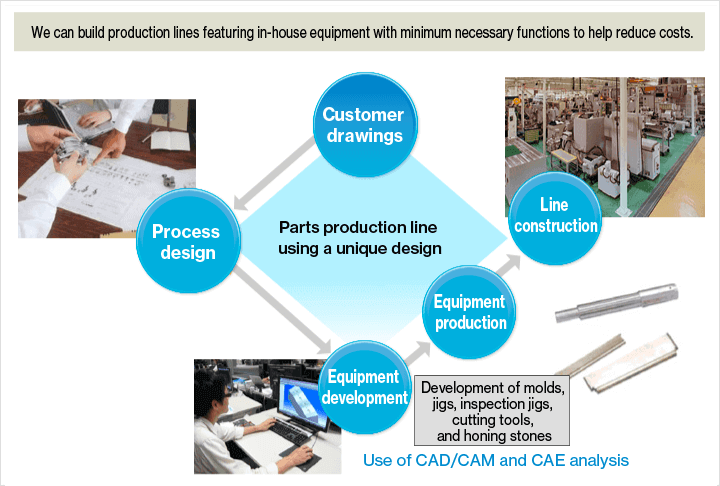

In-house Production of Equipment, Jigs, and Molds

We offer optimal machining methods using in-house machining equipment, molds, and jigs.

Heat Treatment

Heat and Surface Treatment

Heat treatment

Heat treatment is a key process that affects the properties of metals.

Nissin has developed its own heat treatment processes. These processes use automated equipment to ensure safe and high-quality heat treatment.

In addition to offering batch carburizing and carbonitriding, we are also able to provide subzero treatment, vacuum hardening, and copper brazing.

Surface treatment (cooperating plants)

We offer strong and rigid DLC treatment and hard chrome plating as well as copper plating to prevent carburization.

Lineup of Mass-produced Parts

Contact us about our products

| Tel: | +81 772-62-7007 |

|---|---|

| Fax: | +81 772-62-7068 |

| Department in charge of mass-produced parts: | New Parts Sales Section |